- #Magmasoft metal temputure full#

- #Magmasoft metal temputure software#

- #Magmasoft metal temputure iso#

- #Magmasoft metal temputure plus#

Supply chain efficiency reduces time to market and engineering costs, emphasizes collaboration and yields sound manufacturing processes that will increase customer competitiveness. In today’s environment, Premier is seeking all possible ways to be competitive and work together to find solutions that ultimately benefit the entire supply chain.

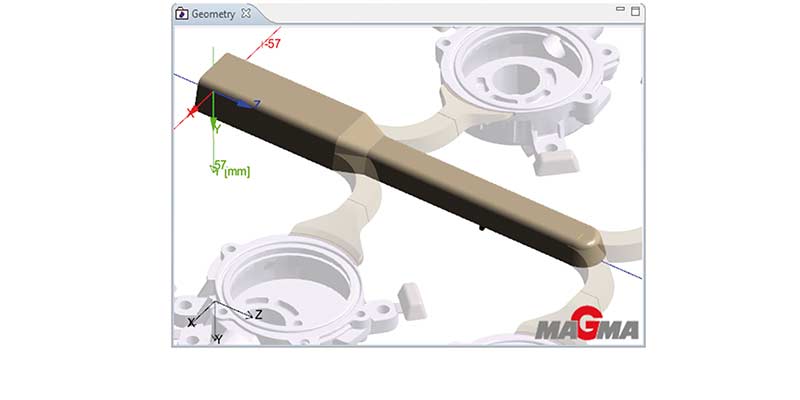

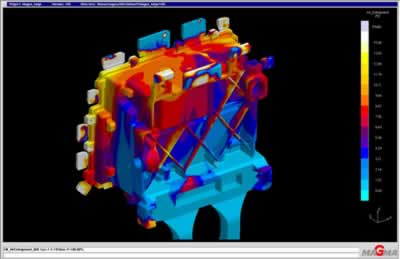

This technology-based strategy, combined with years of experience serving the global foundry market, allows Premier to optimize its designs for castability, quality and overall lowest cost. MAGMASOFT ® blends science, technology and experience from diverse areas of the casting process to create a package that utilizes the complex physics of casting to simulate the results prior to creating the mold. Premier’s engineering group utilizes MAGMASOFT ® to optimize the casting design as well as to refine the casting process from the outset.

#Magmasoft metal temputure software#

One of the company’s most effective engineering tools is MAGMASOFT ®, provided by MAGMA Foundry Technologies, which is a software used to assist engineers, designers and buyers in the metalcasting industry. To better serve its customers, Premier employs such advanced software as Solidworks, MAGMASOFT ® and other engineering tools to enhance customer confidence in tool life, product quality and efficient manufacturing processes, through a more predictive and trackable engineering protocol.

#Magmasoft metal temputure plus#

Its engineering team boasts 50+ years experience in metalcasting, plus the latest advancements in the aluminum foundry industry. The Technology Center will now be available to any Premier customer or potential customer who wishes to work closely with the Premier Engineering Team to quickly and accurately develop new products or re-engineer already existing ones. This progressive approach to working with customers by utilizing advanced technical tools in an R&D facility will now be referenced as the Technology Center at Premier Aluminum. Its current goal is to achieve the desired casting quality by further reducing costs and decreasing time to market for its customers.

#Magmasoft metal temputure full#

Premier has invested in all necessary tools and facilities to enable full collaborative engineering with its customers. Premier positions its capability in the market as a one-stop shop for finished machined, permanent mold aluminum castings. The company serves the quantity casting market, from a few hundred castings per year to annual volumes of fifty thousand and more.

#Magmasoft metal temputure iso#

Schaumburg, IL – Premier Aluminum is an ISO 9001-2008 certified permanent mold aluminum casting and machine shop in Racine, Wisconsin with a reputation for partnering with its customers to find flexible and cost-effective solutions for a variety of products. The process improvements which were run to improve die life, show that by modifying the die start-up procedure, the scrap rate can be reduced making the process more profitable.Wisconsin foundry prospering from its use of technology, including MAGMASOFT ® simulation software for metalcasting The modified die start-up procedure had a negligible effect on the die surface stress fluctuation, with a beneficial reduction in scrap.

From this, a saving of four castings per start-up can be made, reducing scrap by 4.5%, leading to lower manufacturing costs, reduced energy usage and increased useful die life. Changes to the die start-up procedure, by switching off the die internal water cooling for the first four casting cycles, results in the die heating to operating temperature in fewer casting cycles, resulting in fewer castings being scrapped before the die achieves steady state operating temperature. The findings from this paper indicate that the die surface stress decreased by 44% when the die is pre-heated to 150☌, and decreases by 57% when the die is pre-heated to 200☌, in comparison to when the die is started "cold" with an initial temperature of 20☌. ABSTRACT Die pre-heating has a beneficial effect on die life, by reducing thermal shock and stress fluctuations on the die surface.

0 kommentar(er)

0 kommentar(er)